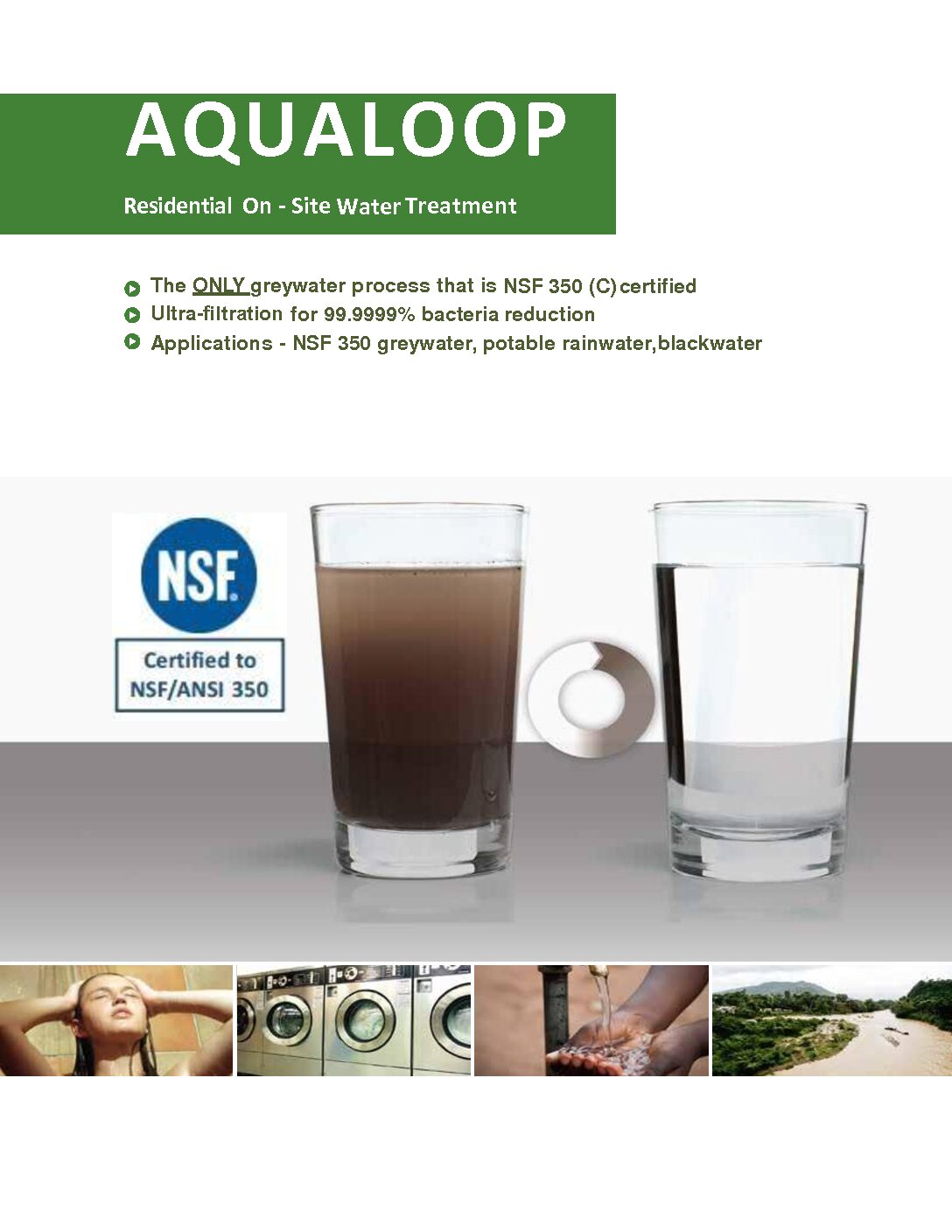

Aqualoop Greywater Treatment

The Aqualoop greywater treatment technology is a moving bed-membrane bioreactor MB-MBR which sounds very high tech and complicated. Let’s break it down. It is not that complicated.

Step 1: Pre-filter

The AQUALOOP pre-filter is self-cleaning and keeps hair, lint and other debris out of the process. The filter is showered off to flush these contaminants down the drain. Filters are sized for flow up to any size building.

Step 2 – Biological Treatment

How this step works:

For greywater treatment, biological treatment breaks down organics. For rainwater and surface water treatment, we skip this step to still achieve drinking water standards.

Step 3 – Ultra-filtration

Patented AQUALOOP membrane cartridges are the core of the water treatment process and the Aqualoop advantage. The membrane’s special hollow fibers are designed to effectively exclude bacteria and viruses from passing to the NSF 350 treated water tank. The ultrafiltration membrane has an effective pore size of 0.02-microns to remove contaminants with 6 log reduction of bacteria (99.9999%) and 99.7% (almost 3 log) virus removal. The membranes stay clean extra long with built-in backwash controls and air scouring.

AQUALOOP can improve the water quality without chemical additives such as chlorine, which has proven hazardous to health (to say the least!). It is a known carcinogen.

AQUALOOP’s special cartridge and membrane design allows for a long service life of up to 10 years with only minimal maintenance.

That’s it! Pre-filter, aerate, and filter. There is no additional treatment necessary to assure NSF 350 (C) quality water. This is how we can minimize maintenance time and cost.